Do you need to remove Arsenic from your water system? Contact us today for an application review.

Advanced Sealing Technology

Mechanical seals for process pumps, ideal for ANSI pump configurations

Advanced Sealing Technology (AST) manufactures a complete line of cartridge and component mechanical seals for process pumps. The AST 70 single cartridge seal has become the industry standard for harsh applications.

The AST 70 is a simple-to-install, unitized cartridge mounted, balanced, multiple spring mechanical seal which requires no measuring for installation. The seal faces are protected from damage and contamination from dirt and foreign particles.

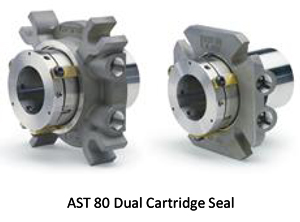

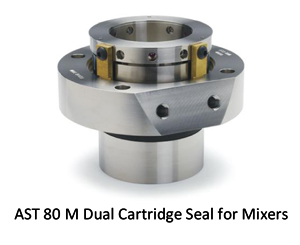

The AST 80 dual cartridge seal incorporates liquid shear pumping to remove heat from the seal faces, and can be operated with a pressurized barrier or non-pressurized buffer fluid system.

Field Re-buildable

No more waiting for seal repairs, and no more worries about installing exchange seals that might have previously held hazardous materials, because the AST 70 is easy to rebuild on site using standard tools.

No Measurement Required

Simply slide the seal onto the shaft, bolt down the gland, tighten the set screws, and remove the centering blocks.

Easy Replacement on Split Case and Vertical Pumps

No pump teardown required. Just slide the seal over the end of the shaft.

Easy Impeller Adjustment

Adjust impeller clearance without removing the seal or dismantling the pump.

In-Stock Availability

AST 70 seals are available off-the-shelf to fit most ANSI pumps, including enlarged bore pumps, without modification. Seals are in stock to fit many split case, positive displacement, and vertical turbine pumps.

Custom Engineered Seals

AST can design and build special AST 70 seals for vertical turbine pumps, large split case pumps, and other systems that require more than a standard seal. Rebuild parts are still off-the-shelf.