Seal-Less Positive Displacement Diaphragm Pumps for Heavy Duty Applications

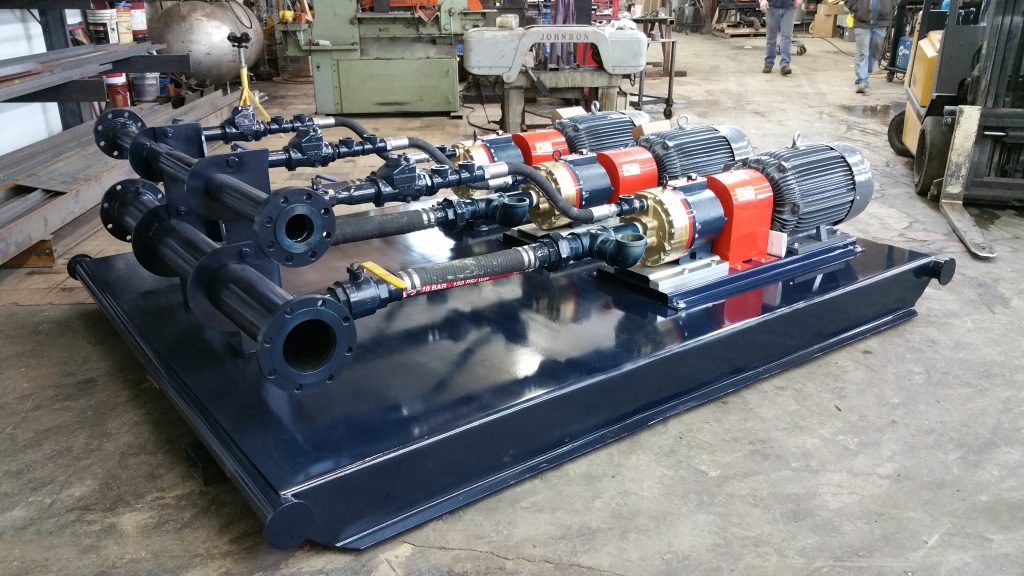

Applied Process is proud to offer AMERICAN MADE Hydra-Cell Industrial Pumps from Wanner Engineering.

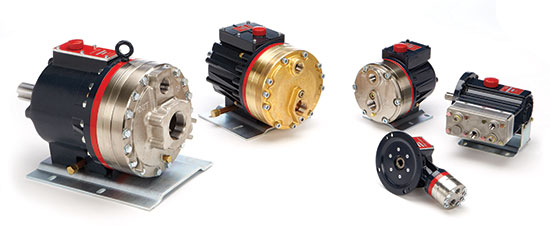

Designed and built with a seal-less pumping chamber, Hydra-Cell D Series positive displacement diaphragm pumps HAVE NO SEALS, PACKING OR CUPS TO LEAK OR REPLACE. Because all bearings and moving parts are isolated from the fluid being pumped, Hydra-Cell D Series pumps can reliably pump chemicals, reclaim water, abrasives, slurries, seawater and many other fluids, either hot or cold, that would quickly destroy other pumps.

In addition, Hydra-Cell positive displacement pumps CAN RUN DRY INDEFINITLY without damage to the pump. The Hydra-Cell multiple-diaphragm design delivers a virtually pulse-less, linear flow so there is no need for expensive pulsation dampeners.

Hydra-Cell D Series pumps are available with both metallic and non-metallic pump ends and can be direct driven with electric, pneumatic or hydraulic motors.

How Hydra-Cell Positive Displacement Pumps Work

“Simply Built to Last”

The precise performance and long life of Hydra-Cell heavy-duty diaphragm pumps keep plants and equipment running day after day without interruption.

- American made

- No mechanical seals, cups or packing to leak or replace

- Minimal maintenance and downtime

- Handles abrasives and particulates that would destroy other pumps

- Variety of models for low to high viscosity fluids

- Pumps for full spectrum of flow capacities and pressure ratings

- Self-priming and can run dry without damage

- Multiple-diaphragm design for pulse-less operation, linear flow eliminates the need for pulsation dampeners

- Choice of polypropylene, brass, ductile iron, and stainless steel pump heads

Hydra-Cell D Series Positive Displacement Pumps

| Maximum Capacity | Maximum Discharge Pressure psi | Maximum Operating Temperature ˚F | Maximum Inlet Pressure | Weight | |||

| Model | GPM | Non-metallic | Metallic | Non-metallic | Metallic | psi | Lbs. |

| D04 | 2.9 | N/A | 2500 | N/A | 250˚ | 500 | 37 |

| D10* | 4.3 | N/A | 1500 | N/A | 250˚ | 250 | 48 M 35 N-M |

| D10 | 8.8 | 350 | 1000 | 140˚ | 250˚ | 250 | 48 M 35 N-M |

| D12 | 8.8 | N/A | 1000 | N/A | 250˚ | 250 | 63 |

| D15 | 15.5 | N/A | 2500 | N/A | 250˚ | 500 | 145 |

| D17 | 15.5 | N/A | 2500 | N/A | 250˚ | 500 | 145 |

| D35** | 23.1 | N/A | 1500 | N/A | 250˚ | 250 | 257 |

| D35 | 36.5 | N/A | 1200 | N/A | 250˚ | 500 | 257 |

| D66 | 65.7 | 250 | 700 | 120˚ | 200˚ | 250*** | 500 M 295 N-M |

* D10 @ 790 rpm maximum ** D35 @ 790 rpm maximum *** D66 max inlet pressure 50 psi for non-metallic models

D10 Series Positive Displacement Pumps

| Maximum Flow Rate: | 8.8 gpm |

| Maximum Pressure: | 1500 psi for Metallic Pump Heads 350 psi for Non-Metallic Pump Heads |

The Hydra-cell D10 positive displacement pumps are widely used in car wash applications are built heavy-duty to pump thick, soapy foam and fluids with chemicals and high solids content.

The D10 is shaft driven with NPT ports or ANSI flanges. It comes standard with cast aluminum housings and a choice of brass, cast iron or polypropylene pump heads. The D10 can also be configured with stainless steel pump heads and ANSI flanges when required.

D12 Series Vertical Positive Displacement Pumps

| Maximum Flow Rate: | 8.8 gpm (33.4 l/min) |

| Maximum Pressure: | 1000 psi (69 bar) for Metallic Pump Heads |

The high-pressure Hydra-Cell D12 pump is the vertical configuration of the Hydra-Cell D10, and an excellent, smaller footprint replacement for a vertical multi-stage centrifugal pump.

Often used in machine tool coolant applications the D12 Series pumps are designed to have the pump head submerged into the coolant sump and typically have a coarse (40 mesh) suction screen on the inlet port to prevent fouling of the internal check valves.

The D12 is flanged for NEMA 182/1843, 213/215TC C-faced motor (NPT ports). It comes standard with cast aluminum housings and a choice of brass, cast iron or 316 stainless steel pump heads.

Downloads:

Watch the Hydra-Cell High Pressure Diaphragm Pump Video

Hydra-Cell Focuses On Pumping Solutions

• Metering pumps

• Plastic pumps

• Flow Control pumps

• Dosing Pumps

• High Pressure Pumps

• Injection pumps

• Parts washing pumps

• Machine Coolant pumps

• Low Flow pumps

• Multi-Fluid pumps

D35 Series Positive Displacement Pumps

| Maximum Flow Rate: | 36.5 gpm |

| Maximum Pressure: | 1500 psi for Metallic Pump Heads |

The Hydra-Cell D35 Series pumps tolerate non-ideal operating conditions and are most commonly used in high-pressure applications or when handling dirt fluids.

Like other Hydra-Cell positive displacement pumps, the D35 is able to run dry without damage and is excellent for high volume applications like car washing, pressure washing, critical pumping applications, such as automotive plants, oil refineries, chemical processing plants, or paper mills.

D35 pumps are capable of precision flow rates from 4 to 36.5 GPM at discharge pressures from 50 to 1200 psi.

D66 Series Positive Displacement Pumps

| Maximum Flow Rate: | 65.7 gpm |

| Maximum Pressure: | 700 psi for Metallic Pump Heads 250 psi for Non-Metallic Pump Heads |

The Hyrda-Cell D66 Series are industrial positive displacement pumps that are high flow, medium-range pressure pumps capable of handling viscous fluids with abrasives and particulates. With multiple diaphragm chambers, the D66 pumps deliver a very smooth pumping operation with over 160 pulses per second at a 65 GPM flow rate.

The D66 features larger pump heads and ANSI flange inlet/outlet ports. They can address caustic fluids such as seawater, reclaim water and slurries, and used in applications like desalination systems, agricultural fertilizer, centrifugal pump seal flushing, industrial cleaning systems, and large machine tools coolant systems.

Hydra-Cell D66 Pumps can run dry and tolerate fluid temperatures from -20˚F to 200˚F. They come standard with cast aluminum housings and a choice of brass, nickel-plated ductile iron, 316L stainless steel, or polypropylene pump heads.